JLM technology reduces occupational injuries

How do you reduce occupational injuries / lifting injuries in the workplace?

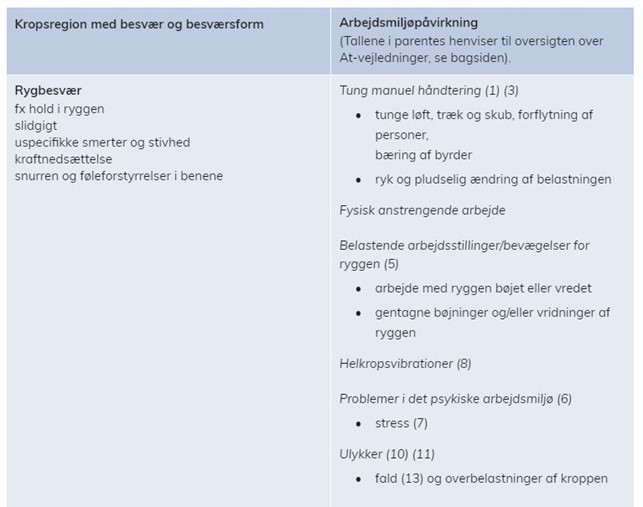

Statistics from the Danish Working Environment Authority shows some of the problems/illnesses that have arisen in employees who have been exposed to a short- or long-term impact of various stresses in the workplace. Here you can see, among other things, that Back problems in many cases are caused by “heavy lifting, pulling and pushing, moving people, carrying loads”, “jerking and sudden change of load”, “working with the back bent or twisted” and “repeated bending and/or twisting of the back”.

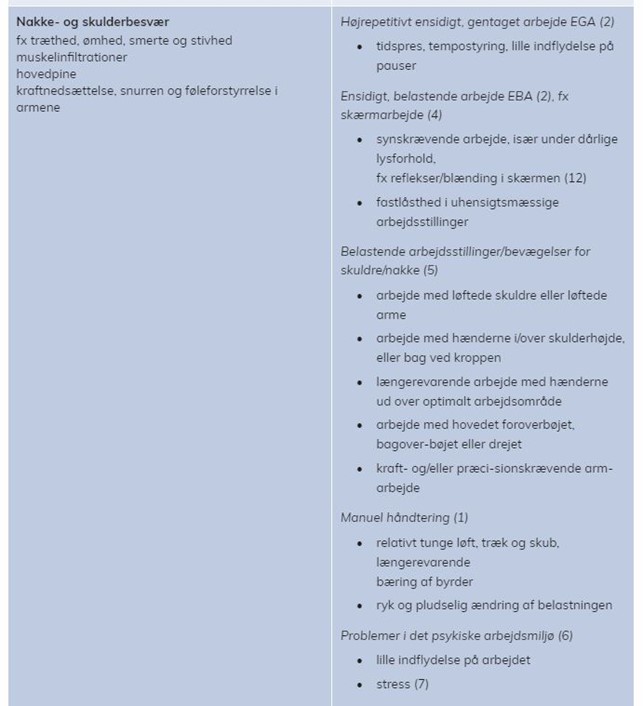

Neck and shoulder problems

are often caused by factors such as “working with lifted shoulders or raised arms”, “working with the hands in/above shoulder height or behind the body”, “prolonged work with the hands beyond the optimal working range”, “relatively heavy lifting, pulling and pushing, prolonged carrying of loads” and “jerks and sudden changes in load”.

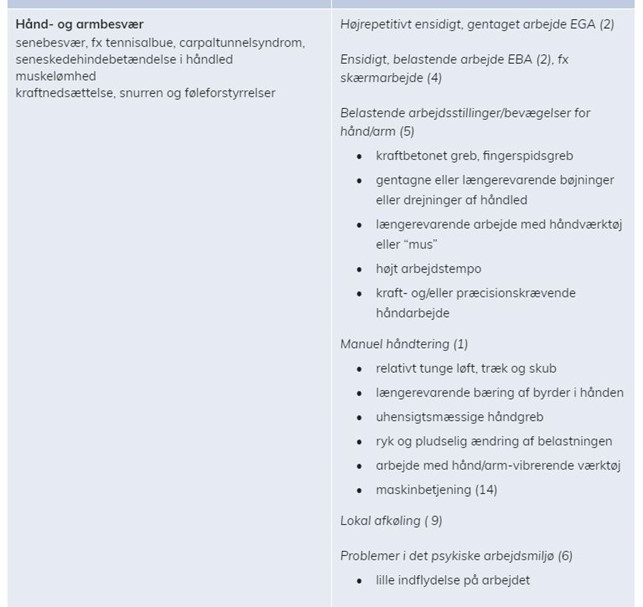

Reported occupational injuries involving hand and arm problems are in many cases due to e.g. “relatively heavy lifting, pulling and pushing”, “prolonged carrying of loads in the hand” and “jerking and sudden change of load”.

Source: The Danish Working Environment Authority – Musculoskeletal disorders, diseases and impacts at work

(https://at.dk/regler/at-vejledninger/arbejdsrelateret-muskel-skeletbesvaer-d-3-4/)

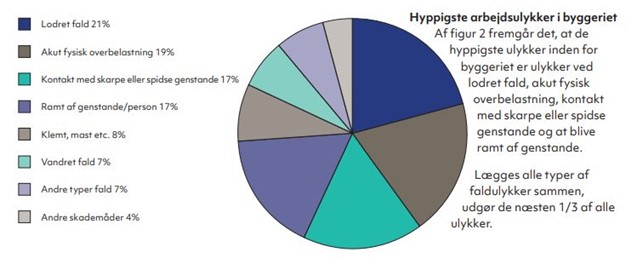

The chart below from the Danish Working Environment Authority shows percentages of the most frequent occupational accidents/occupational injuries in the construction industry in the period 2015-2019. Here you can see that 19% of these accidents are due to Acute physical overload.

Source: The Danish Working Environment Authority – Reported occupational accidents according to AML 2015-2019 that have occurred in construction, by type of injury (type of accident)

(https://at.dk/media/6533/faktaark-ulykker-byggeriet.pdf)

The efforts to completely avoid occupational injuries and lifting injuries in the workplace are commendable, but probably not likely anytime soon. However, the development of lifting equipment for virtually every industry today has come so far and operates at such a high level that a large part of the physical load has been taken off the shoulders of the employees.

Over the past ten to twenty years, physical lifting work has been made easier through the development of unique and user-friendly lifting equipment to prevent such occupational injuries.

For companies, it is of course recommended to acquire approved lifting equipment for demanding lifting tasks, both to spare employees, increase efficiency and create an optimal working environment. Hard physical work with, for example, demanding and heavy lifting can in many respects discourage many from training in such industries. This is of course due to fear of occupational injuries and wear and tear injuries already at an early age, which can potentially lead to sick leave and the risk of permanent injury as a result of overload in occupational injuries.

We would like to provide an example of revolutionary lifting equipment that has made the working day easier for millions of people in the labour market, and at the same time increased efficiency and turnover for companies.

A vacuum lifter is a tool for handling and lifting heavy elements in many industries, and it is not a complex special tool that requires further training and courses to use. Most vacuum lifters are user-friendly, and the control panel has been reduced to a minimum for ease of use. The vacuum lifter, as the name indicates, works via a strong vacuum suction that hooks onto the unit to be lifted.) The motor operation in a vacuum aerator creates the suction, and in JLM Teknik’s standard range, we operate with four variants of vacuum lifters:

- Alpha: The vacuum lifter for sacks or the slightly larger and heavier tasks. Depending on the configuration, this model lifts from 20 to 300 kg.

- My: Is almost a copy of the Alpha, but for the light lifting and the small hand. This lifts up to 65 kg.

- Ropes: The vacuum loop with pistol grip. A vacuum lifter with the possibility of very high speed. This can lift up to 65 kg. (Coming soon).

Vacuum lifters are unbeatable for handling items such as sacks, cardboard boxes, wooden boards, plastic boxes and a sea of other items/products. Porous materials can be difficult to handle when lifting, but here too the vacuum lifter is flexible and efficient. Should the energy supply to the vacuum vacuum be interrupted, the vacuum lifter will not let go of the workpiece, but will instead lower the workpiece safely against a surface, and only then does the suction cup release the workpiece so that no work injuries or damage to the workpiece being lifted occur. A vacuum lifter is thus one of the safest when it comes to lifting and handling items in the workplace.

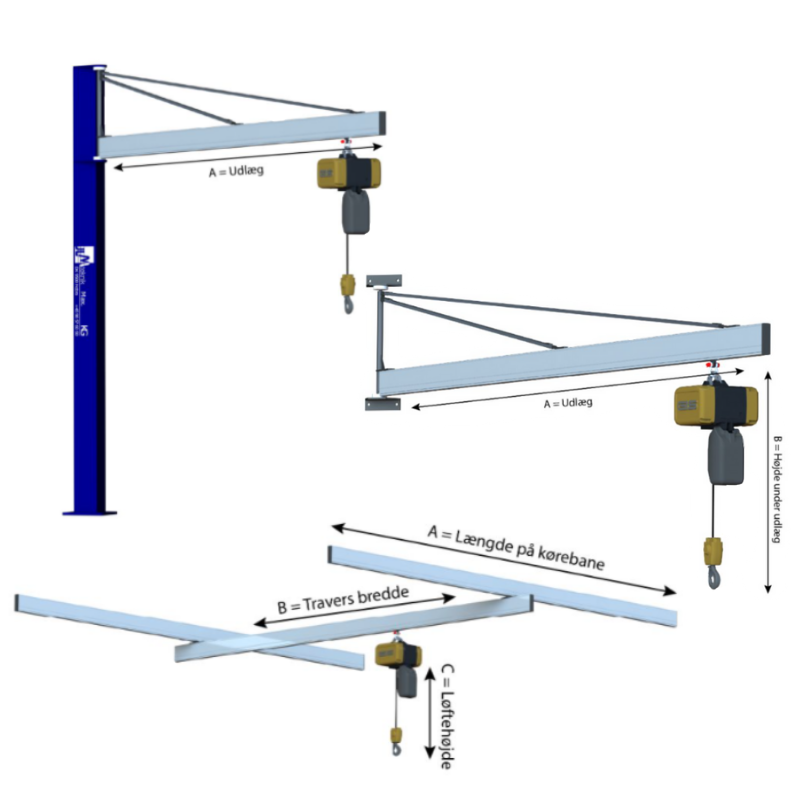

In addition to vacuum lifters, there are many other strong solutions in lifting equipment that can reduce physical strain and thereby prevent occupational injuries and lifting injuries for employees. JLM teknik sells many solutions for optimal conditions with regard to lifting equipment in the workplace – regardless of industry. Of course, your needs depend on your industry and what topics you need to lift. Solutions include jib cranes, column cranes, Powr-Grip vacuum suction, hoists and hoists, as well as lifting trolleys. JLM teknik has a large selection of quality lifting trolleys with integrated load plate that can lift from 50 kg up to 250 kg.

Fight and reduce occupational injuries and lifting injuries with the correct lifting equipment in the workplace.

You can see the range of vacuum lifters below: